FDM Printing

What is FDM Printing?

Fused Deposition Manufacturing (FDM) is one of the more common 3D printing technologies and one of the most versatile.FDM creates parts by extruding a plastic filament material through a nozzle and stacking it layer by layer in a table.FDM allows for simple parts to be printed with high accuracy, but due to the limitations of the process any overhanging features will require support material and will need to be removed after the print is complete. Therefore more complex parts with overhangs will be slightly less accurate.

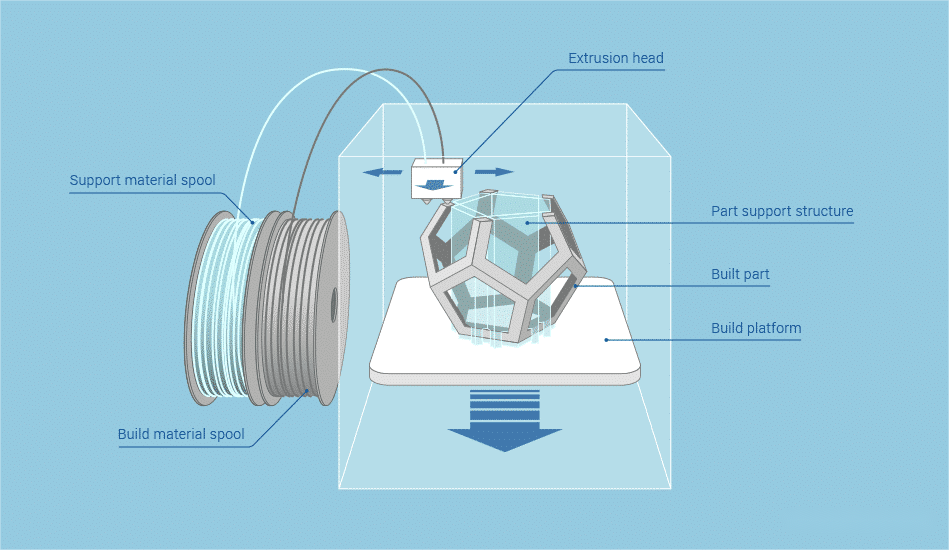

How FDM 3D Printing Works

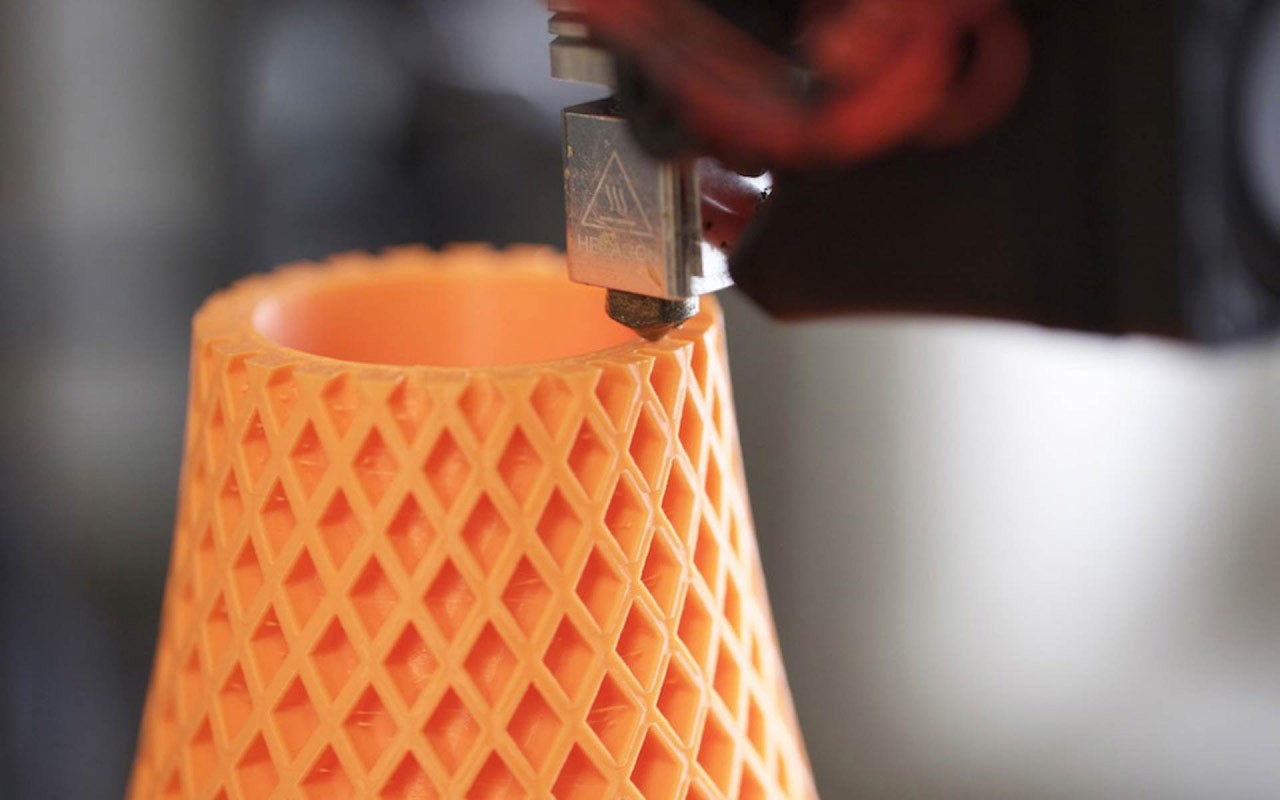

3D printers using FDM technology build parts by extruding thermoplastic filaments, layer by layer, starting from the bottom. The process is fairly simple:

Pre-processing: Pre-build software slices and positions the 3D CAD file, then calculates the path of the base thermoplastic and the location of any required support material.

Production: A 3D printer heats the thermoplastic to a semi-liquid state and then deposits it in tiny beads through an extrusion channel. If support or cushioning is needed, the 3D printer can also deposit removable material as a support.

Post-processing: Users can break off the support material or dissolve it with cleaners and water to get a usable part

Advantages of FDM 3D Printing:

*Cost-Effective:

FDM printers and materials are generally more affordable compared to other 3D printing technologies, making it accessible for hobbyists, educators, and small businesses.

*Material Variety:

A wide range of thermoplastic materials is available, each with different properties such as flexibility, strength, and heat resistance. Some advanced FDM printers can also print with composite materials, including wood-filled, metal-filled, and carbon-fiber-reinforced filaments.

*Ease of Use:

FDM printers are relatively easy to set up and operate, with many models designed for consumer and educational use. They often come with user-friendly software and straightforward maintenance procedures.

*Scalability:

FDM technology is scalable, with printers available in various sizes, from small desktop models to large industrial machines capable of producing sizable parts.

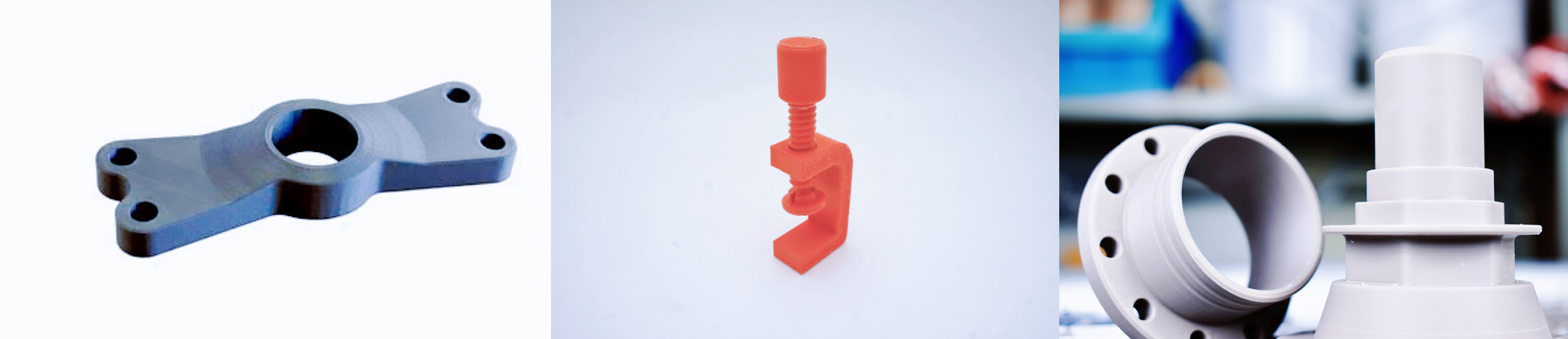

FDM 3D Printing Applications:

FDM is a great choice for prototyping and small production runs where parts need to be produced in a specific material.FDM can print in a large variety of materials including ABS, PC, and even performance materials such as Ultem and nylon, wood-like wood-plastic materials. It offers endless possibilities for crafts.

FDM common materials

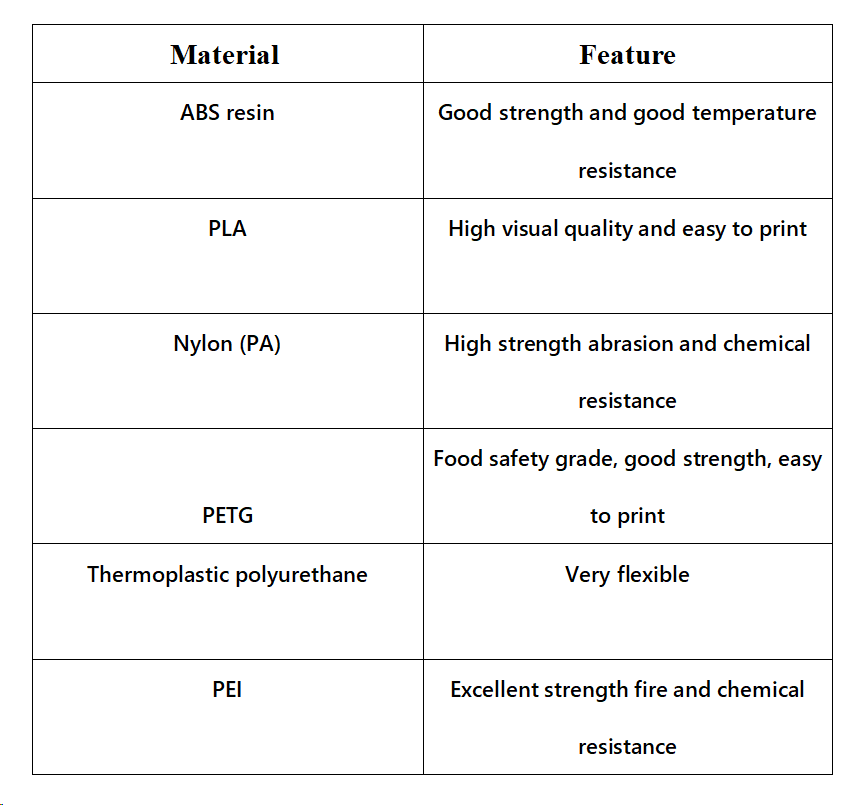

FDM has a wide range of materials available, including commodity thermoplastics such as PLA and ABS,

engineering materials such as PA, TPU and PETG, and high-performance thermoplastics such as PEEK and PEI.

FDM materials can affect mechanical properties and accuracy. We summarize common FDM materials as follows:

FDM 3D Printed Parts Gallery