SLS Printing

What is SLS 3D Printing?

What is SLS 3D Printing?

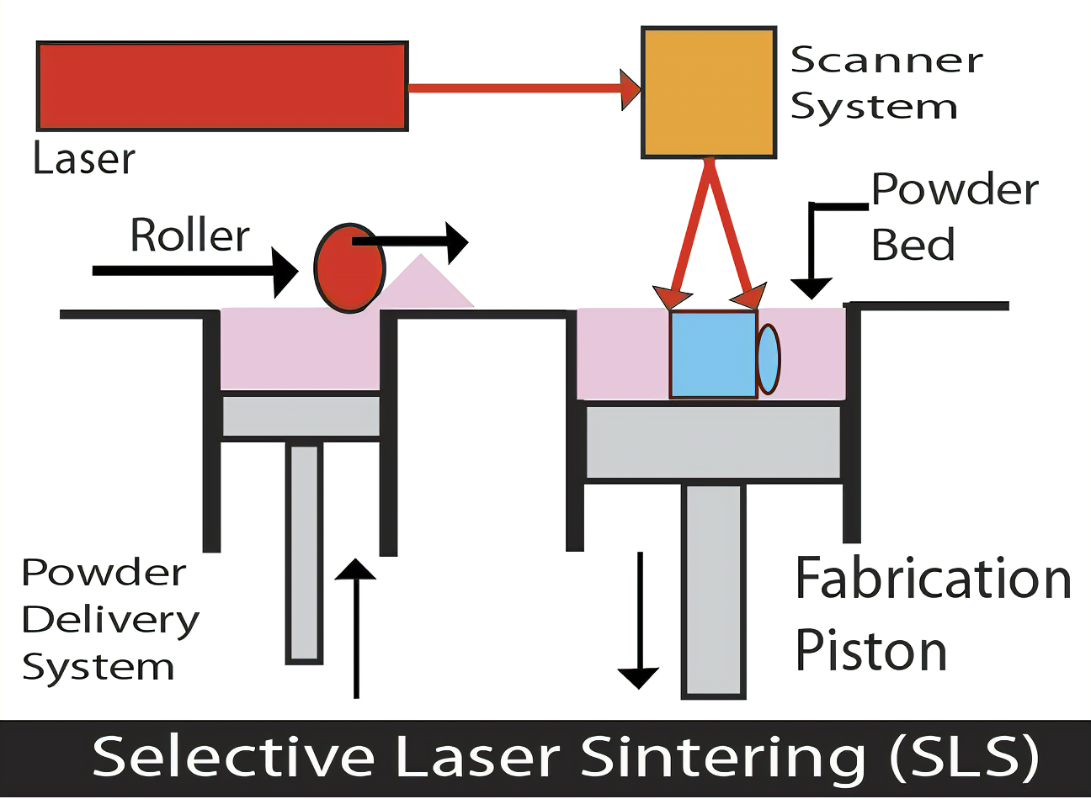

SLS, short for Selective Laser Sintering, is an additive manufacturing process that is part of the Powder Bed Fusion family. In the SLS process, a laser system is used to sinter polymer powder, fusing the particles together and creating the part layer by layer. SLS materials are granular thermoplastic polymers.

SLS technology is widely used for functional component prototyping and low-volume production. SLS offers high design freedom, high precision and excellent mechanical properties. All designers should consider its key strengths and limitations to maximize their technical capabilities.

Advantages of SLS 3D Printing

1.Wide range of printing materials:

The high precision of molded products, the wide range of materials, and the short production cycle make it a popular choice for production and processing in the industrial sector.

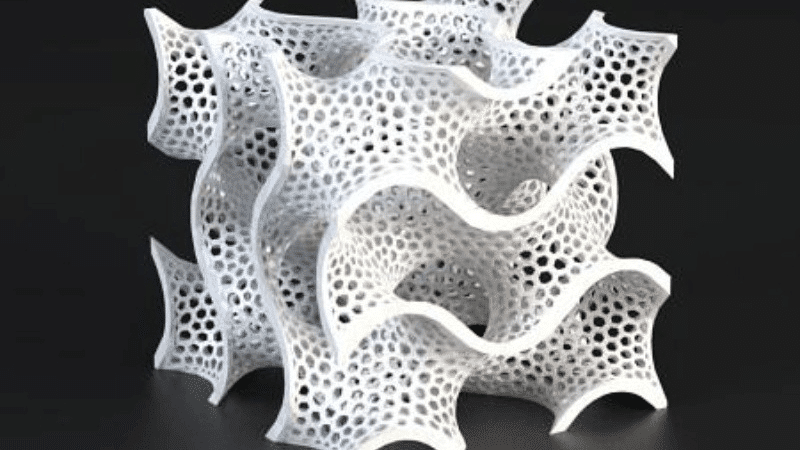

2.Processing complex geometries:

3D printing technology breaks through the tradition and realizes integrated design and manufacturing. Complex geometries can be constructed more easily and at no additional cost.

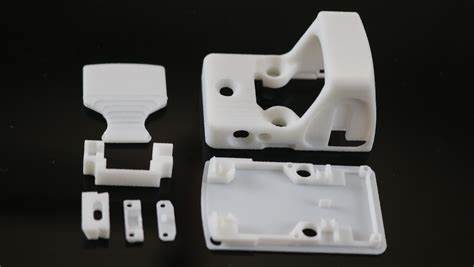

3.Ideal for functional parts and rapid prototyping:

SLS printing technology enhances the project process by producing functional end-use parts on demand.

4.Short production cycles, fast and cheap:

Compared to traditional molding methods, SLS 3D printing technology can produce parts without the need to open a mold, eliminating the time required to open a mold and significantly increasing manufacturing efficiency.

How SLS Rapid Prototyping Works

The powder is preheated to a temperature slightly below the melting point and then flattened using a roller or scraper. Under computer control, a high-intensity CO2 laser selectively sinter parts based on layered cross-section information, adhering to the molded part below and sintering the next layer as it is completed. When all sintering is complete, excess powder can be removed and the sintered part is available.

Applications for SLS Prototyping Services

1.Automotive: Prototyping and producing lightweight, durable parts.

2.Aerospace: Manufacturing complex components with high strength-to-weight ratios.

3.Medical: Creating custom prosthetics, orthotics, and surgical instruments.

4.Consumer Goods: Producing customized products, such as footwear and eyewear.

5.Industrial: Fabricating functional parts and tooling for manufacturing processes.

Our SLS Printing Parts Gallery