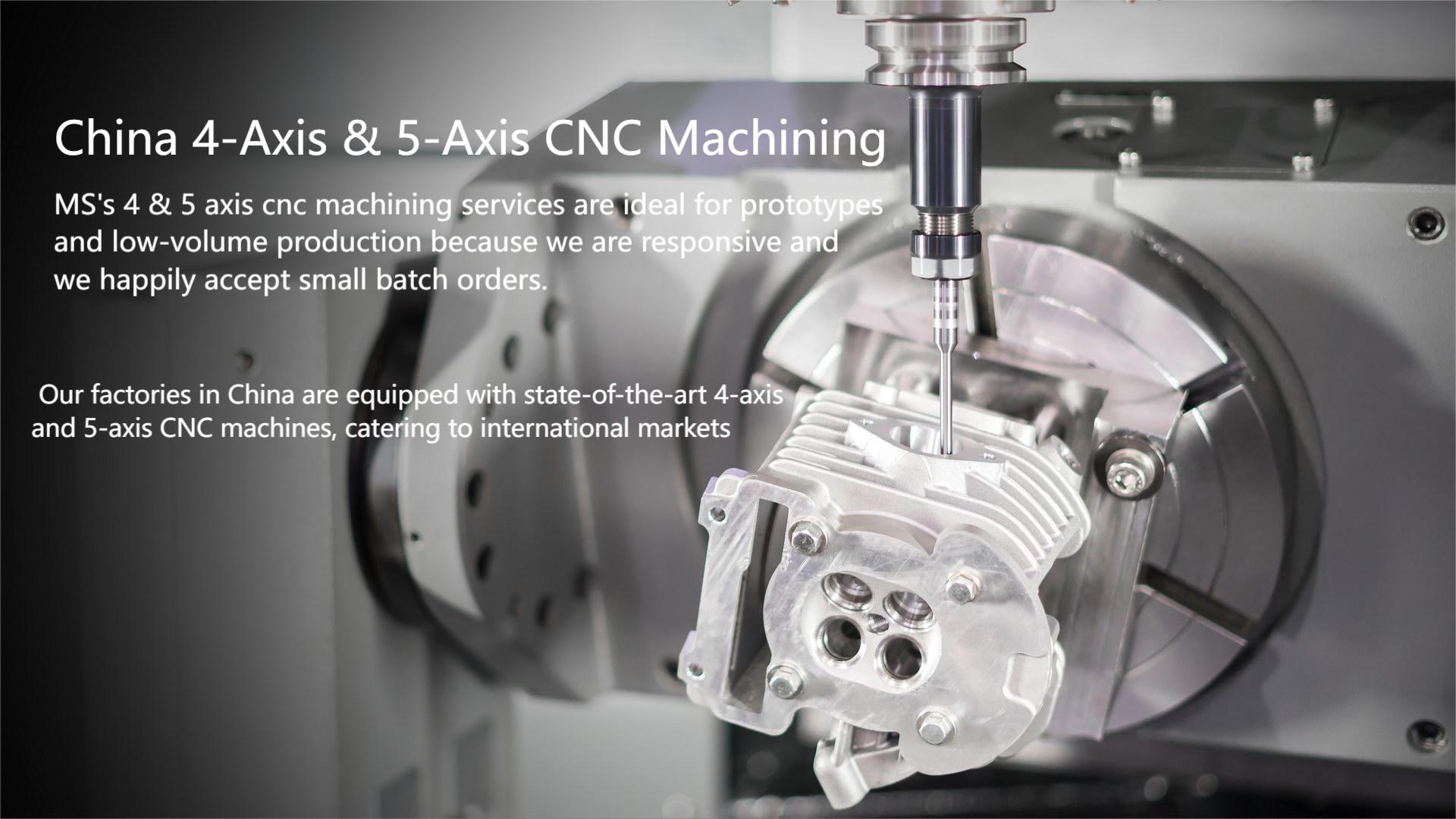

China 4-Axis & 5-Axis CNC Machining

4-axis CNC machining and 5-axis CNC machining: What is the difference?

4-axis CNC machining and 5-axis CNC machining: What is the difference?

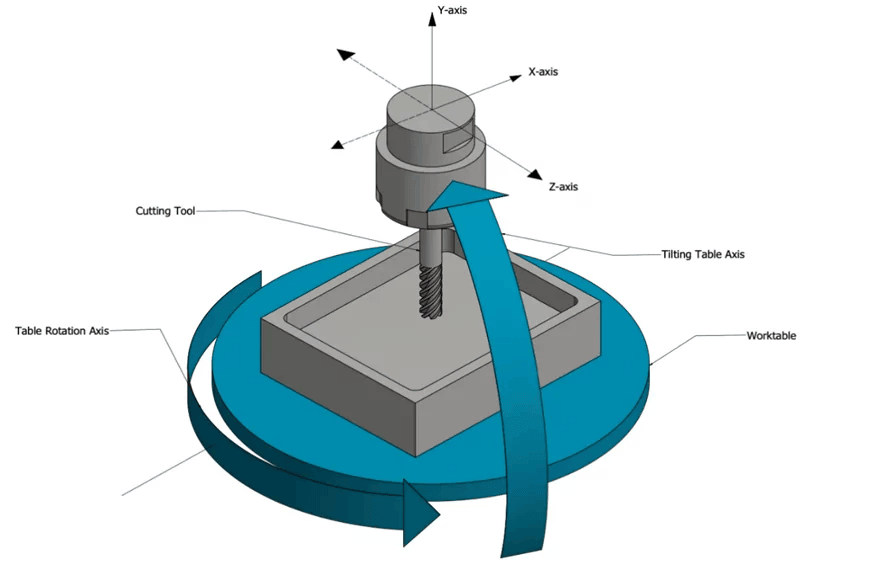

4-axis and 5-axis CNC machining refer to the number of directions in which the cutting tool can move or rotate to work on the material. These advanced CNC machining techniques allow for the production of complex parts with high precision. Here's a detailed look at the differences between the two

4-Axis CNC Machining

In 4-axis CNC machining, the cutting tool operates along four axes:

*X-Axis: Horizontal movement,left to right.

*Y-Axis: Horizontal movement,front to back.

*Z-Axis: Vertical movement, up and down.

*A-Axis (Rotation around X-Axis): The workpiece or the cutting tool rotates around the X-axis.

5-Axis CNC Machining

In 5-axis CNC machining, the cutting tool can move along five axes:

*X-Axis: Horizontal movement, left to right.

*Y-Axis: Horizontal movement, front to back.

*Z-Axis: Vertical movement, up and down.

*A-Axis (Rotation around X-Axis): The workpiece or the cutting tool rotates around the X-axis.

*B-Axis (Rotation around Y-Axis): The workpiece or the cutting tool rotates around the Y-axis.

Summary of Differences:

*Movement Capabilities: 4-axis machines can rotate the workpiece around one axis, while 5-axis machines can rotate around two different axes, allowing for more complex part geometries.

*Complexity: 5-axis machining is capable of handling more complex geometries and is generally preferred for high-precision parts that require intricate details.

*Cost and Setup: 5-axis machines tend to be more expensive and require more sophisticated programming and setup compared to 4-axis machines.

Why Choose MaiSheng as Your 5 axis CNC Machining Manufacturer

#As a leading China 4 &5 axis CNC machining manufacturer, MaiSheng understand the importance of offering cutting-edge technologies to meet diverse industry needs. Our expertise in CNC axis types enables us to tackle complex projects with ease, ensuring superior dimensional accuracy and intricate detailing. Whether you require 4 axis cnc machining or 5 axis CNC machining services, we have the proficiency and state-of-the-art machinery to bring your designs to life.

#At MaiSheng, we take pride in our commitment to delivering micro CNC 5 axis machining services that exceed expectations. Our team of highly skilled engineers and technicians possess a deep understanding of the intricacies involved in producing miniature components with utmost precision. With our micro CNC 5 axis capabilities, we can accommodate the most intricate designs, providing you with flawless results for your specialized projects.

#Choose us for affordable 5 axis CNC machining services without compromising on quality. We combine our competitive pricing with a dedication to maintaining stringent quality control measures throughout the manufacturing process.

China 4- axis & 5-axis CNC Machining Applications

5-axis Machining Applications:

• Complex Surfaces: Five-axis machining excels in producing complex surfaces, such as freeform shapes, curved contours, and multi-sided parts. The additional rotational axes allow the cutting tool to approach the workpiece from various angles, resulting in smooth and precise surface finishes.

• Multi-Angle Machining: With five-axis machining, manufacturers can machine parts from multiple angles without repositioning the workpiece. This capability is particularly useful for machining features on different sides of a part or accessing hard-to-reach areas, reducing setup time and improving efficiency.

• Aerospace Components: The aerospace industry often requires intricate and lightweight components with complex geometries. 5-axis CNC service enables the production of aerospace parts like turbine blades, engine components, wing sections, and fuselage structures with high precision and accuracy.

4-axis CNC Machining Applications:

• Complex Contours: 4-axis CNC machining is ideal for creating complex contours on parts, such as curved surfaces, sculpted shapes, and intricate profiles. It allows the cutting tool to approach the workpiece from different angles, resulting in precise and intricate geometries.

• Undercuts: With the rotational movement provided by the fourth axis, 4-axis machining can easily produce undercuts. Undercuts are features or cavities that cannot be accessed directly by a cutting tool in a straight line. Industries like aerospace and automotive often require undercuts for components like molds, turbine blades, and impellers.

• Spiral or Helical Features: 4-axis machining is well-suited for creating spiral or helical features, including threads, screw threads, and grooves. The rotational movement enables the cutting tool to produce these features with precision and accuracy.

• Prototyping: The versatility and flexibility of 4-axis CNC machining make it an excellent choice for rapid prototyping. China 4-axis CNC machining allows for the efficient production of prototypes with complex shapes and contours, enabling designers and engineers to test and refine their designs before mass production.

China 4-Axis & 5-Axis CNC Machining Advantages

The advantages of 4-axis machining and 5-axis cnc service compared with ordinary 3-axis machining center are mainly reflected in the following points:

01

The available tools have been greatly expanded. 4 axis machining and 5-axis cnc service tools can use more processing tools at one time: turning tool, milling cutter, boring cutter, drill bit, spherical cutter, etc. China 4-axis cnc machining and five-axis machining make the processing technology choose more.

02

More processing technologies make the clamping time shorter and less: one-time clamping can complete more processing procedures, making it possible not to need secondary clamping. Greatly reduce the quality problems of parts caused by secondary clamping.

03

No fixture (customized fixture): all processes are completed in one clamping, and there is no need to customize the clamping fixture due to the needs of processing technology. China 4-axis and 5-axis CNC machining directly reduce cost and time.

04

No fixture (customized fixture): all processes are completed in one clamping, and there is no need to customize the clamping fixture due to the needs of processing technology. China 4-axis and 5-axis CNC machining directly reduce cost and time.

05

Extend the comprehensive life of the tool: the free choice of multiple processes makes the tool make the best use of everything, and there is no need for the milling cutter to waste time completing the boring process, which makes the wear position of each kind of cutter fixed and convenient for subsequent work such as inspection and maintenance, which directly improves the service life of the tool.

06

Improve production concentration: a machine can complete the functions and work of a lathe, milling machine, boring machine, drilling machine and other machine tools at one time, which greatly improves the production concentration.

07

Improve processing production and enterprise efficiency: To sum up, the quality of parts processed by 4-axis and 5-axis CNC machining is guaranteed, reducing processing loss, improving concentration and facilitating enterprise management. Directly reduce processing costs and improve enterprise efficiency.

Why Choose MaiSheng As Your 4-Axis & 5-Axis CNC Machining Supplier?

Extensive Experience

As one of the most professional 4-axis & 5-axis CNC machining suppliers in China, MaiSheng boasts years of experience in the CNC machining industry. Our expertise covers a wide range of applications and industries, allowing us to handle diverse projects with precision and efficiency. With a proven track record, we have earned the trust of numerous clients worldwide.

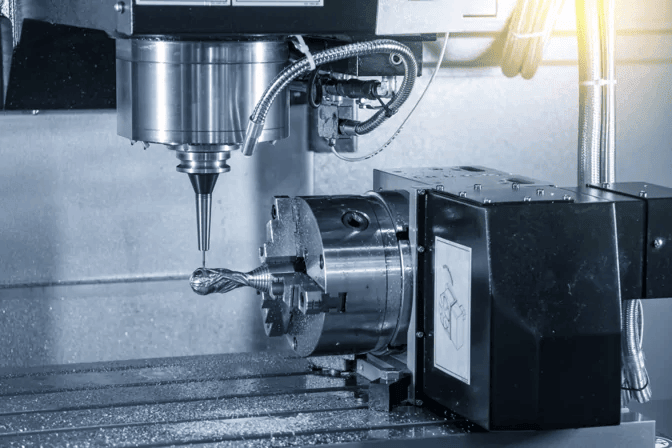

Advanced Technology

We continuously invest in state-of-the-art machinery and cutting-edge technologies to ensure that our clients receive the highest quality products. Our commitment to innovation enables us to deliver exceptional accuracy, speed, and repeatability in our 4-axis & 5-axis CNC machining processes.

Skilled Engineering Team

With our own 4-axis CNC machining factory, our team of highly skilled engineers and technicians is dedicated to providing superior craftsmanship. They possess a deep understanding of CNC machining principles, materials, and techniques. With their expertise, they can offer valuable insights, optimize designs, and deliver precise, custom solutions.

Customization Options

We understand that every project has unique requirements. With MaiSheng, you can expect tailored 4-axis & 5-axis CNC machining solutions to suit your specific needs. Our team will work closely with you to understand your project's objectives and provide personalized recommendations and solutions.

Competitive Pricing

We believe that high-quality 4-axis & 5-axis CNC machining should be accessible and affordable.MaiSheng offers competitive pricing without compromising on the quality of our products. We strive to provide excellent value for your investment, making us a cost-effective choice for your affordable 5-axis cnc.

Timely Delivery

We recognize the importance of meeting deadlines and delivering projects on time. With efficient project management and streamlined processes, we ensure that your orders are completed within the agreed-upon timeframe. You can rely on professional 4-Axis & 5-Axis CNC Machining Supplier-MaiSheng for prompt and reliable delivery.