CNC Milling services

Powerful Precision CNC Milling Service

Powerful Precision CNC Milling Service

Milled at higher rates of progress and with greater precision, resulting in the finishing of parts with precise features and specifications.

CNC milling is controlled by a computer and uses rotating, multi-point cutting tools to gradually remove material from a workpiece and produce a custom-designed part or product. The process is suitable for processing a variety of materials, such as metals, plastics, and wood, and produces a variety of custom-designed parts and products. It is also suitable for producing high-precision, close-tolerance parts in prototypes, one-offs and small to medium-sized production runs. The versatility of the CNC milled parts process allows it to be used in a wide range of industries and a variety of part features and designs, including slots, chamfers, threads and cavities.

CNC Milling process

The first step is to use CAD software to design the part with

the desired geometry. You can then submit your 3D CAD files

online and get an instant quote for free. After all details have

been checked and finalized, your digital design will go into

production immediately.

1.Design 3D CAD models

2.Convert CAD models into CNC machine programs

3.Start the machining process via the interface or control panel

4.Remove bulk material from the workpiece to obtain the desired

shape

5.Perform high-precision CNC milling operations

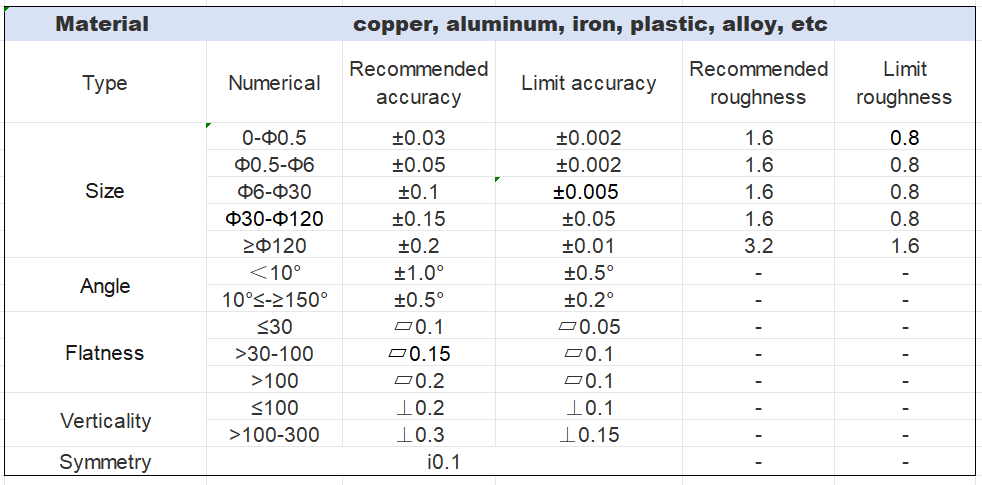

CNC Milling Process Design Guideline

The CNC Milling processing capabilities and scope that precision machining China can provide are as follows:

Why Choose Maisheng as your China CNC Milling Companies

OEM & ODM Specialist

Located in Shenzhen, the heart of China's technology and manufacturing center, we serve as your CNC mill turn center, providing large-scale support for product improvements and cost reductions for your product line.

Extensive Experience

MaiSheng experienced and skilled project engineering team will analyze the process for each part, customize the most appropriate machining solution for your CNC milling projects, and provide an all-in-one service with low cost and high quality.

Standard Packaging

MaiSheng is committed to providing top quality. We offer special packaging options for your CNC milling parts to ensure that each part is delivered undamaged, and Richconn guarantees that you get exactly what you order.

High Precision Equipment

The workshop is fully equipped with high-precision machining equipment (5-axis CNC machine tools, Swiss CNC lathes, etc.) and inspection instruments (three-dimensional yuan, two-dimensional yuan, micrometer, spectrometer, etc.), with an accuracy of up to +/-0.01mm, and fast delivery.

Mold Service

Our business includes optimization of product design analysis, budget proposals, first implementation of conceptual products, rapid prototyping, mass production of molds and support for modification of mold design and manufacturing, as well as small batch production of molds.

Applications of CNC Turning and Milling

01

CNC milling is more applied to complex surfaces, step surfaces, helical surfaces (threads), inclined surfaces (taper surfaces), chamfers, grooves (keyways, grooves, T-grooves, etc.) with complex shapes, and complete processing of parts without replacement.

02

In part processing of CNC milling working, automatic tool change can greatly improve efficiency. Because of its flexible processing characteristics, NC milling is the absolute main processing technology in the whole processing industry.

Advantages of CNC Milling

01

CNC milling is especially suitable for parts with strong adaptability to materials and difficult to control size or parts with particularly complex contour shapes.

02

CNC milling operation can process parts that are difficult or impossible to be processed by ordinary turn-milling machine tools, such as linear surfaces, circular arc surfaces, etc.

03

CNC milling operation can process parts that are difficult or impossible to be processed by ordinary turn-milling machine tools, such as linear surfaces, circular arc surfaces, etc.

04

The equipment has a high degree of automation, especially the equipment with tool magazines and automatic tool changes. Reduce labor intensity and repeated the tooling process. When the quality needs to be checked, the processing can be stopped at any time, and the continuous production can not be adjusted after the inspection.

Different Types of CNC Milling Machines:

Generally speaking, the type of CNC milling machine is defined based on its number of axes. The higher the number of axes, the greater the ability to manufacture complex parts and create cutting angles.

Three-axis CNC milling machine:

The cutting tool can move along the X, Y and Z axes.

4-axis CNC milling machine

Similar to a lathe, more complex parts can be made by adding an extra degree of motion by rotating on a vertical axis

5-axis CNC milling machine

The most complete milling machine that adds two additional degrees of motion by increasing the rotation of the table and spindle. Parts can be machined in just one setup.

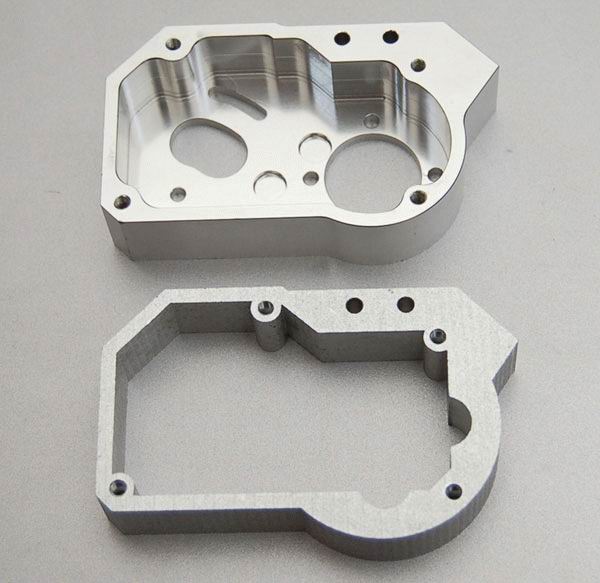

Display of Custom CNC Milling Projects From Our Customer