CNC turning services

MaiSheng Precision CNC Turning Design Guideline

MaiSheng Precision CNC Turning Design Guideline

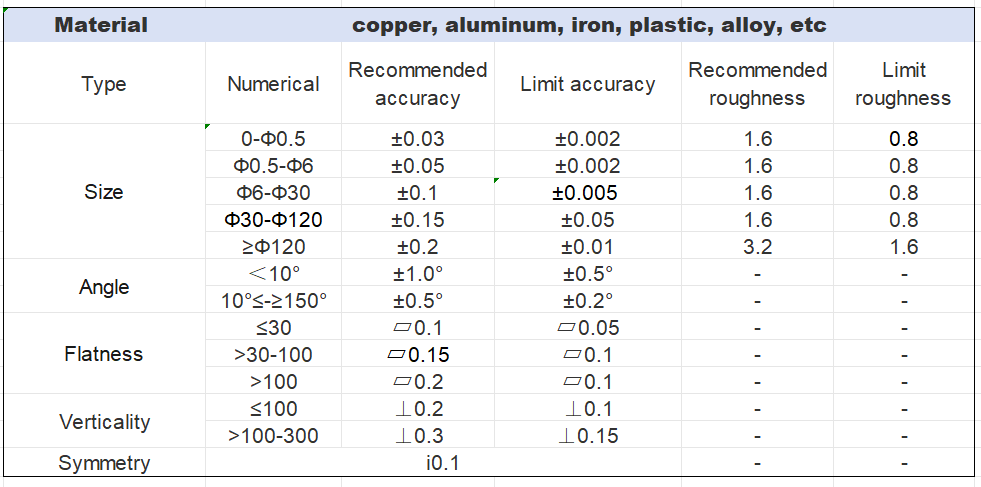

The CNC turning processing capabilities and scope that our company can provide are as follows:

What is CNC Turning?

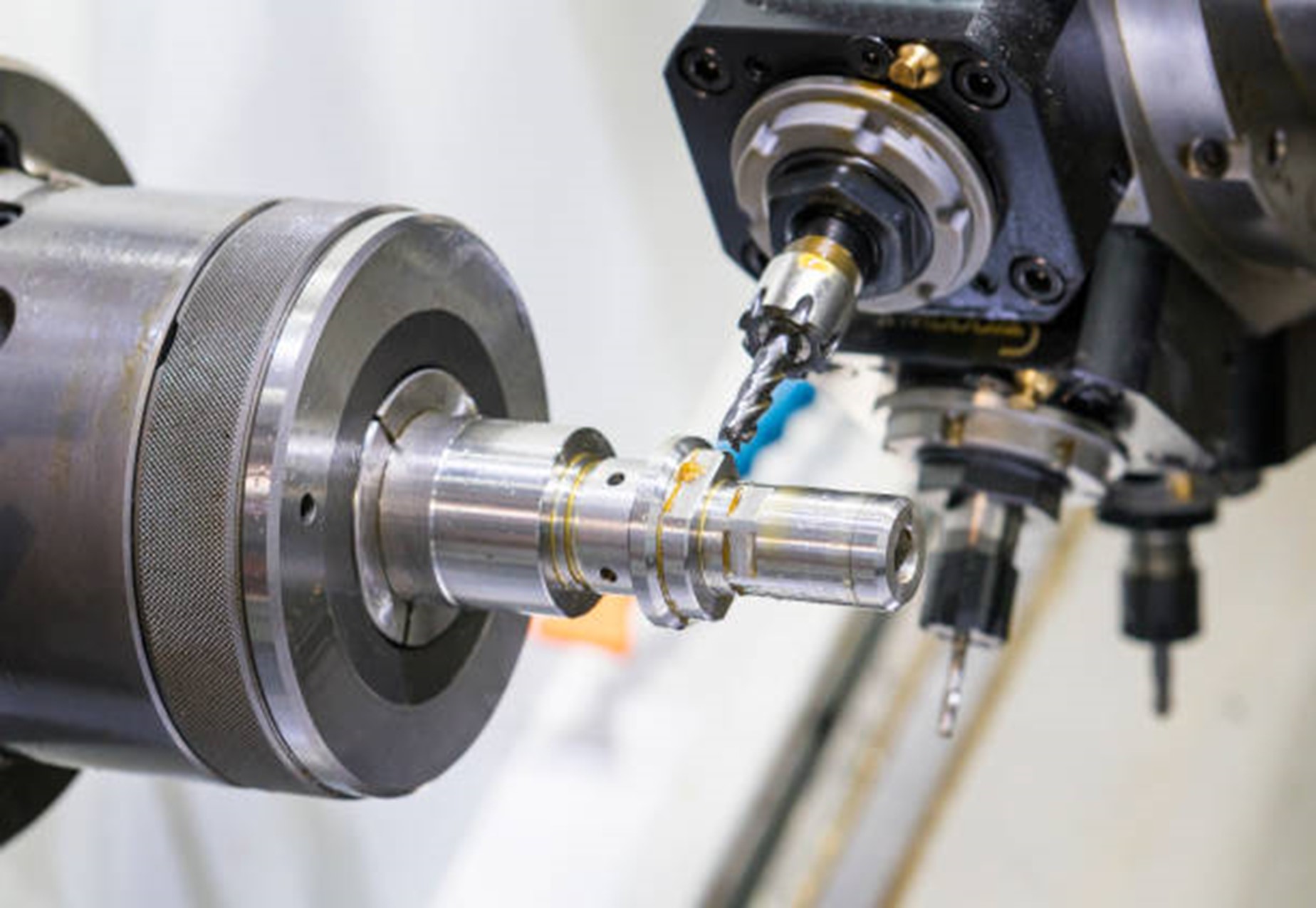

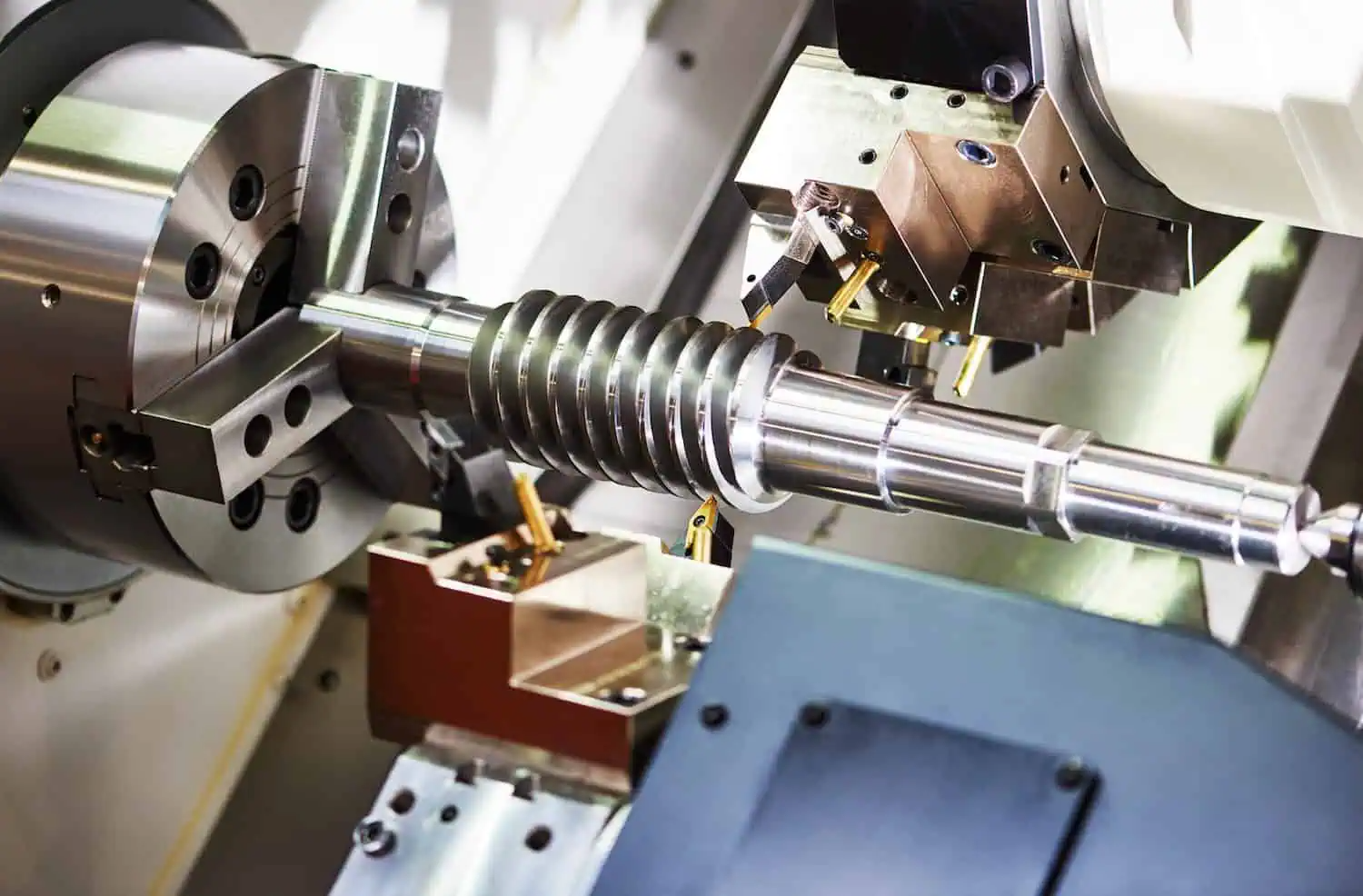

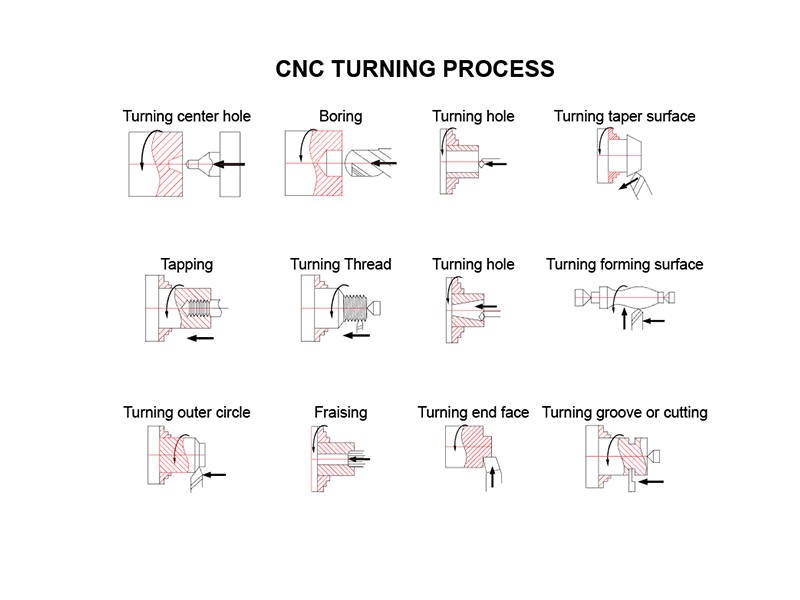

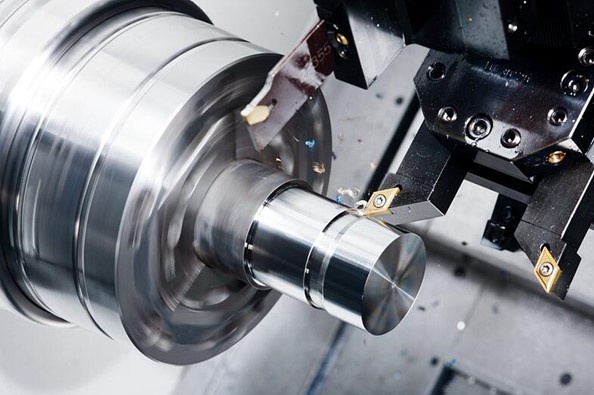

CNC turning is a subtractive machining process in which a cutting tool removes material from a rotating workpiece. The cutting tool is typically mounted on a computer-controlled turret, and the workpiece is mounted on a chuck or faceplate. As the automated tool moves across the surface of the workpiece, it removes material to create the desired shape.

CNC turning is widely used in industries such as aerospace, automotive, medical and manufacturing where precision and consistency are critical. It offers many advantages, including high precision, efficiency and the ability to produce complex parts with relative ease. CNC turning is a versatile and cost-effective method of producing cylindrical parts and is an integral part of modern manufacturing processes.

Why Choose MaiSheng as your CNC Turned Parts Manufacturer

Own Factory

The factory is its own property with an area of nearly 15,000 square meters. It can provide customers with everything from product design to prototype verification, mold manufacturing to small batch production of products. There are more than 200 employees, including nearly 150 CNC technicians with more than 11 years of experience and quality engineers.

Mass Production

It has more than 100 large-scale precision CNC machining centers (processing strokes up to 2500MM), five-axis machines, four-axis machines, three-axis machines, 6 fully automatic vacuum forming machines, CNC milling machines, SMF CNC stamping, drilling machines, and sandblasting machines. machine. As well as precision testing equipment for two-dimensional and three-dimensional measuring instruments.

Strictly Control Quality

It has ISO9001 quality management system and EOS quality management system certification, complete measurement and physical and chemical inspection equipment, advanced testing instruments and equipment, and complete testing methods. There are more than 10 existing instruments, including two-dimensional and three-dimensional measuring instruments and precision testing equipment.

Our Equipment

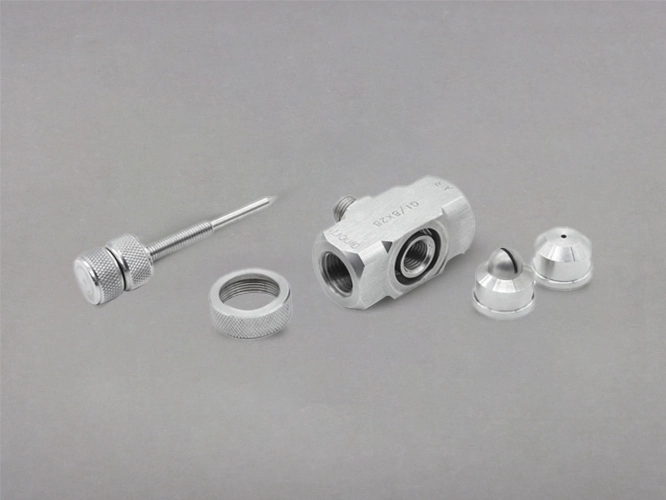

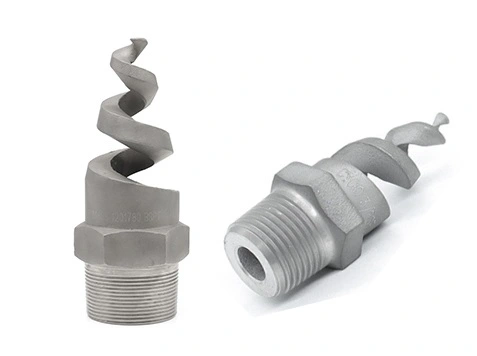

CNC Turned Parts Gallery

Explore our extensive collection showcasing cnc precision turned parts prototypes and components supplied by our valued clientele.

CNC Turning Machine Parts

Acquiring familiarity with the parts of a CNC turning machine is essential to grasp the process of CNC turning. Turning machine parts vary by manufacturer, kind, and capacity. It’s important to note that all CNC turning machines have several common parts:

*Control unit: The controller is the brain of the operation, receiving input from the operator and translating it into actions

* Spindle: It is the part of the machine that holds and rotates the workpiece

* Turret: The turret is a platform that holds and indexes the cutting tools

*Tool holder: Tool holders are adjustable devices holding cutting tools on the turret

*Cutting tool: Cutting tools are used to remove material from the workpiece

How Does a CNC Turning Machine Work?

Turning machines were operated manually until computer numerical control (CNC) was introduced. This opened up a lot of potential for errors. Like a painter seeing the final result in his head before beginning work, the machinist had a visual picture of what he wanted to create.

However, when computer numerical control (CNC) was introduced, turning suddenly became a very precise and accurate multi-step procedure. There are a few steps involved in creating a part using a CNC turning machine:

First, the product's CAD model is designed. For this, several computer-aided design (CAD) software can be used. Each component of the final product must be specified in the design.

The format of CAD files is not recognised by CNC turning machines. Instead, they follow a set of digital instructions called G-Code that tells them where to go and what to do in three-dimensional space. For this reason, it is essential to transform CAD files into G-Code. Computer-aided manufacturing (CAM) software is useful in this context. Once a CAD model is complete, the designer sends it to a CAM program, which interprets the data and generates the appropriate G-Code for manufacturing.

The next step is to set up the machine. The operator must prepare the CNC turning machine by mounting the workpiece, clamping the right cutting tool to the turret, and filling the relevant storage with cutting fluid before the CNC program can be performed.

Once the machine is set up, the operator will start turning using the machine’s control panel. The turning process begins when the machine moves the cutting tool across the surface of the rotating workpiece.

Applications Of CNC Turning Parts

CNC machining turning is embodied in a wide range of industries, from our common daily necessities (pots, pans, bowls, cooking utensils) to a variety of aerospace parts, from automobiles, ships, construction machinery, agricultural machinery, telecommunications, electronics and other industries. The basic finished products can be processed by CNC.

01

Daily necessities, especially small household appliances, such as commonly used metal cutting tools and tableware, are especially suitable for some processes to adopt CNC numerical control processing because of their large quantity and standardized processing requirements. In particular, we can provide automatic feeding and reclaiming processing, which greatly improves efficiency and reduces the cost.

02

The parts and components of the automobile industry have the characteristics of high volume and strict requirements. The contemporary automobile has a great rate of resistance to the improvement of automation efficiency in the manufacturing process and the decline in cost. NC machining is applied to all processes of the automobile industry, including engines, gearboxes, shafts, and other parts of all models of trucks, cars, and off-road vehicles.

03

Most mechanical parts of engineering, agricultural machinery, and other machines use CNC processing technology, including various shafts, valves, crankshafts, connecting rods, seals, and other parts.

04

Due to their large quantity and high precision requirements, communications and electronics have a wide range of CNC machining applications, from communication base station radiators to daily mobile phone cameras, watch casings, non-standard automated manufacturing equipment parts, etc. Chinese CNC turning companies are concentrated in the Pearl River Delta and Yangtze River Delta. We have both labor and supply chain advantages in Shenzhen to provide customers with fast and high-quality processing technology services.

Advantages Of CNC Turning

| 01 |

Rapid processing and production in large quantities and short supply cycle. Through the batch copy processing of the program in CNC vertical turning center, without human intervention, multiple machine tools can be processed at the same time, reducing labor and improving efficiency. The cycle can be calculated by hour. |

| 02 |

The sampling cycle is short and the quality is guaranteed. The program is automatically imported, simulated processing, and automatic production to reduce manual errors. The samples can be produced by CNC turning operation quickly every day. The processing accuracy can be tested at any time in the production process to ensure quality. |

| 03 |

The appearance accuracy and quality are guaranteed: we invite professionals to make efficient enterprise processes for the enterprise according to our own enterprise characteristics, so that each processed part has a beautiful appearance (no scra-tches)and consistent size progress (in line with the design requirements), and introduce independent surface treatment and flexible packaging in later surface treatment and transportation so that customers can receive perfect products. |