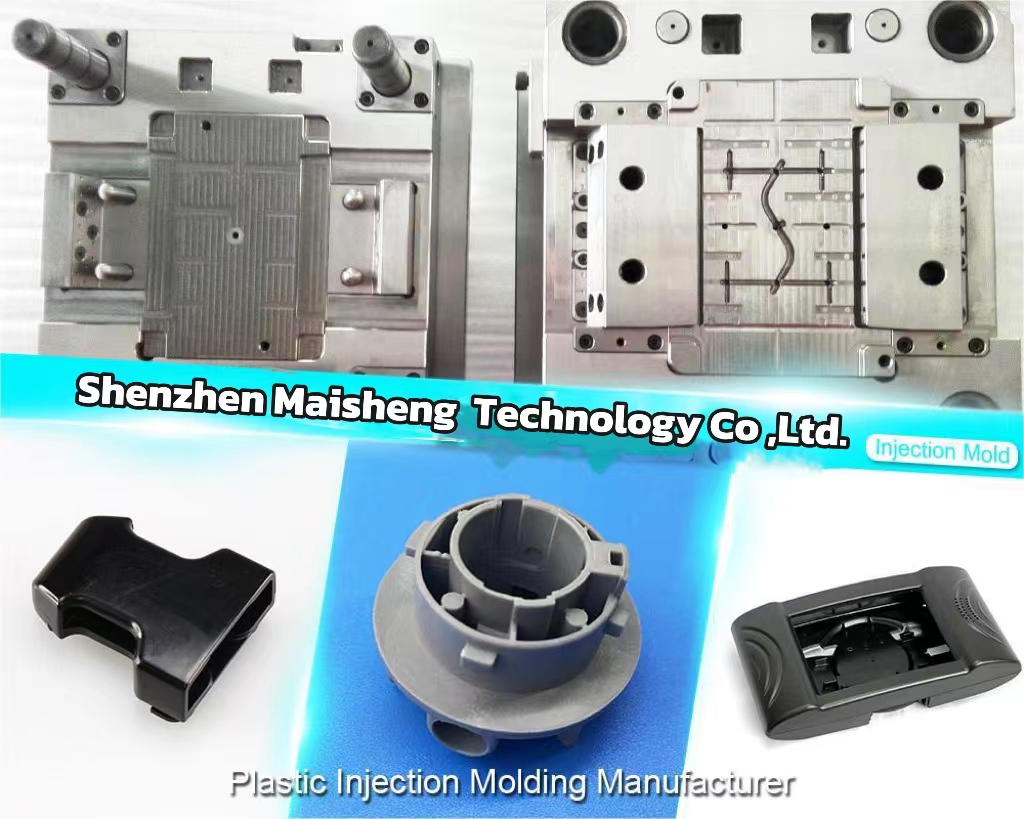

Injection molding services

Our company is committed to providing high-quality injection molding services to meet the needs of various industries. Our injection molding process uses advanced equipment and technology to produce complex, high-precision and high-performance plastic parts. Whether it's small batch production or large-scale manufacturing, we have the flexibility to ensure on-time delivery.

Advantages of Injection Molding

1. Efficiency Injection molding is an efficient process for processing high-volume orders quickly. |

2. High durability The tensile strength of molded parts can be increased by adding fillers to liquid resins |

3. Fineness Molten material can reach every crevice of the mold at high pressure before solidifying, allowing engineers to incorporate complex elements and intricate geometries into their designs. |

4. Cost savings The technology enables efficient, high-yield production, making it possible to produce each part at low cost. Costs can be further reduced by choosing cost-effective and readily available injection mold materials such as aluminum. |

5. Mass production Injection molding is ideal for low-volume production of 250 pieces to high-volume production of over 1,000,000 pieces. Additionally, the use of steel molds in injection molding can speed up mass production of millions of identical parts |

6. Smooth finish Molded parts are ready for packaging and delivery with a clean finish and require no further processing when removed from the mold. |

Injection molding materials:

There are many types of injection molding materials, and different types of plastic materials can be selected according to different application needs and performance requirements. Here are some commonly used injection molding materials:

Special plastics

| Polytetrafluoroethylene (PTFE) |

| Polyethersulfone (PES) |

| Liquid Crystal Polymer (LCP) |

Composite materials

Glass fiber reinforced plastic (GRP) |

Carbon fiber reinforced plastic (CFRP) |

Engineering plastics

Material | Feature |

Polyoxymethylene (POM) | High strength, low friction and wear resistance, often used in precision mechanical parts, gears and bearings. |

Polyimide (PI) | Excellent high temperature resistance and electrical insulation, often used in electronic components and mechanical parts in high temperature environments. |

Polyetheretherketone (PEEK) | High strength, high heat resistance and chemical stability, commonly used in aerospace, medical and automotive industries. |

Polybutylene terephthalate (PBT) | High strength and chemical resistance, it is commonly used in automotive parts, electronic components and home appliances. |

Thermoplastic

Material | Feature |

Polyethylene (PE) | *Low-density polyethylene (LDPE): Flexible and chemically resistant, often used in packaging materials, bottles and toys. *High-density polyethylene (HDPE): High hardness and good wear resistance, often used in pipes, bottle caps and industrial containers |

Polypropylene (PP) | *It is lightweight, tough and resistant to chemical corrosion and is widely used in auto parts, home appliances, food containers and medical equipment |

Polystyrene (PS) | *General polystyrene (GPPS): has good transparency and high hardness, and is often used in food packaging, laboratory vessels and electronic product casings. *High-impact polystyrene (HIPS): has good toughness and is often used in toys, refrigerator linings and electrical casings. |

Polyvinyl chloride (PVC) | *Rigid PVC: Good chemical resistance, often used in pipes, building materials and wire and cable sheathing. *Soft PVC: Soft and often used in hoses, shoe soles and toys. |

Polyethylene terephthalate (PET) | It has high transparency and good impact resistance, and is often used in beverage bottles, food packaging and textiles. |

Polyamide (nylon, PA) | It has high strength and good wear resistance and is often used in gears, bearings, auto parts and industrial machinery. |

Polycarbonate (PC) | It has good transparency and strong impact resistance. It is often used in spectacle lenses, CDs, mobile phone casings and protective covers.

|