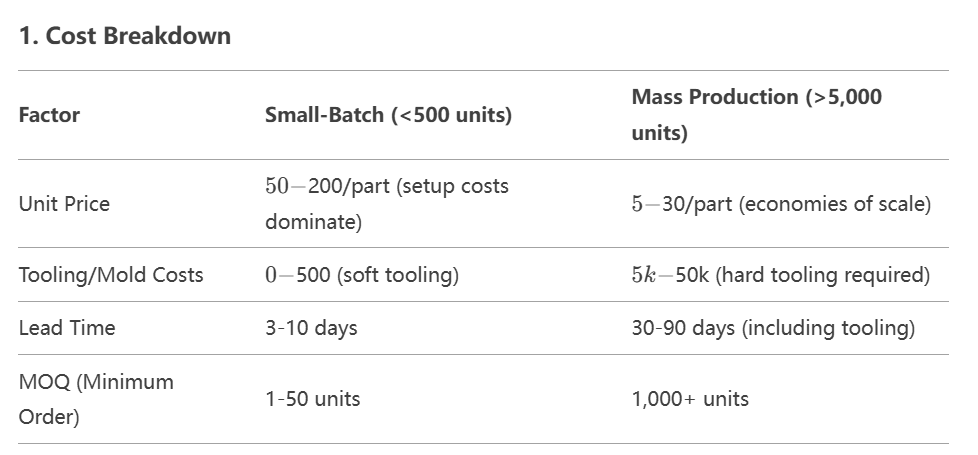

When developing metal parts through CNC machining, choosing between small-batch production and high-volume manufacturing significantly impacts your budget, timelines, and product quality. Let’s break down the key factors to help you decide:

2. When to Choose Small-Batch

✔ R&D/Prototyping

Test 10-50 functional prototypes before finalizing designs.

Critical for medical devices requiring FDA validation.

✔ Customized Components

Aerospace brackets needing material certifications (e.g., AMS 2750 heat treat specs).

✔ Urgent Production

Automotive aftermarket parts requiring 72-hour turnaround.

✔ Niche Markets

Luxury watch components with PVD-coated titanium (low annual demand).

Our Advantage:

Zero tooling fees for orders under 500 units.

15+ CNC machines handle complex geometries in 6061-T6, 316L stainless, etc.

3. When Mass Production Wins

✔ Stable High-Volume Demand

Automotive fasteners requiring 100k+/month output.

✔ Cost-Sensitive Products

Consumer electronics housings where <$0.50/unit savings matter.

✔ Standardized Components

Hydraulic fittings with ASME B16.11 compliance.

Key Consideration:

ROI threshold typically reached at 3,000+ units for common materials like 1018 steel.

4. Hybrid SolutionsMany manufacturers now blend both approaches:

Bridge Tooling:

Use CNC-machured aluminum molds for 500-2k plastic parts (30k steel molds).

On-Demand Restocking:

Maintain digital inventory for repeat orders (e.g., 50-unit batches every quarter).

Regional Micro-Factories:

Distributed CNC hubs cut logistics costs for localized mass production.

5. Decision Checklist

Ask these questions:

Volume Needs: Will demand exceed 1k units/year?

Design Maturity: Are CAD files 100% finalized?

Regulatory Stage: Need ISO 9001/AS9100 certified prototyping?

Cash Flow: Can you afford $10k+ upfront tooling?

Why Partner with Us?

Flexible Scaling: Start with 10-unit batches, seamlessly scale to 10k+ with our network.

Cost Transparency: Free DFM analysis to optimize designs for either approach.

Speed: 65% of small-batch orders ship within 5 business days.